Challenge: To identify opportunities in edible electronics for food and beverage products Client: Global FMCG manufacturer Background: Edible electronics has been an area of interest within the pharmaceuticals for a number of years. The benefits are that the delivery of, and the effect of, drugs can be monitored and measured with the […]

Food Innovation

Challenge: To identify agricultural practices for the natural production of enhanced value crops, through optimisation of specific desired components such as nutrients or functional ingredients. Client: Global FMCG manufacturer Background: Sustainability is a complex topic and with factors, such as growing population and climate change, optimisation of crop yields for enhanced value […]

Challenge: Alternatives to ascorbic acid as anti-browning agents Client: Added value fruit product producer Background: Cut fruits and vegetables are susceptible to browning due to the oxidation of tyrosinase enzyme (Tyr), also known as polyphenol oxidase (PPO). This is often referred to as enzymatic browning and is typically inhibited through the application […]

Challenge: Next Generation Cooking to improve operational efficiency of manufacturing processes Client: Global Food manufacturer Background: A key process step in the production of a wholegrain wheat product is the gelatinisation of wholegrain starch through steam cooking. As part of strategic planning for the ‘factory of the future’, the client is actively […]

Challenge: To identify natural materials, that can be incorporated into a powder based food product, to act as an inert filler, increase the bulk density and act as as a carrier for active ingredients with little or minimal interaction with other ingredients or functional components. Client: Global FMCG manufacturer Background: Increasing the […]

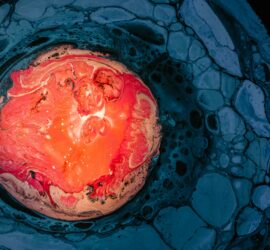

Challenge: Enhance the functionality and organoleptic properties of its products through the application of delayed or controlled release technology, such as encapsulation of functional, active or flavour components. Client: Global FMCG manufacturer Background: Controlling the release of functional or flavour components in food and drink products is beneficial, as it allows the […]

Challenge: A perforated packaging material, either permeable or semi-permeable to allow the controlled release of active ingredients. Client: Global FMCG manufacturer Background: A packaging material, similar to a tea-bag, is used to contain a functional product. The current product is limited in its ability to control the release of the functional components […]

Challenge: A ‘low-’ or ‘no-’ fat coating is required to give the perception of a full fat product. Client: Global FMCG manufacturer Background: The product is fat-free and it is desirable to coat the product in such way so that, when consumed, the immediate impression is one of a full fat product. […]

Challenge: To maximise salivation, or the perception of salivation, in a dry product. Client: Global FMCG manufacturer Background: The product is a dry powder product that is consumed directly, the powder delivers flavour and functional ingredients, but is often considered to be ‘mouth drying’, astringent or de-hydrating as the product is consumed. […]

Challenge: Identify solutions to for value engineering condiments through the use of alternative ingredients, alternative processing or supply chain reliability. Client: Global FMCG manufacturer Background: The products are a range of condiments including low pH emulsions and heated treated sauces. Value, sustainability and supply chain security are pertinent issues that require constant […]